Process Introduction

Nowadays, varies concentration ratio of sulfuric acid are used in the production process of lead-acid battery. Concentration ratio were determined by different types and sizes of battery. Battery formation is one of the most important phases in the production process of lead-acid battery. This step starts with the introduction of a sulfuric acid solution. The precursor material of battery is transformed into active material by the passage of electric current. In chemical reactions, the concentration of H2SO4 is a significant parameter that helps to achieve the correct ratio. After the grooving is complete, batteries are assembled, filled with the correct concentration of sulfuric acid, and then gets fully charged. After a chemical reaction in the battery, the electrolyte will be swaped (secondary feed method) or the sulfuric acid is adjusted (single feed method). Sulfuric acid concentration and electrolyte level must conform to the specified concentration at the end of charging and storage phase. A reliable in-line real-time sulfuric acid concentration measurement can ensure the quality of chemical reaction process and the accuracy of final H2SO4 concentration. GND-15 in-line process refractometer is a star product from ZHYQ for concentration measurement. It will help the manufacturer to ensure their lead-acid battery to meet HGT2692-2007 standard concentration for sulfuric acid in battery.

Problems and Flaws from Current Method

Highly concentrated sulfuric acid used in lead-acid battery is mainly transported by truck to the production site and then dilute H2SO4 to varies required concentration ratio. Small and medium manufacturers store their sulfuric acid in labelled storage tanks by different concentration ratio. Large manufacturers adopt two-stage dilution process. H2SO4 is first diluted into a moderate concentration and store in storage tanks. Then final dilution is occurred at the filling station to dilute H2SO4 into specified concentration. To change the type or size of the battery may leads to a change of concentration at the filling station. Adjusting the concentration of a filling tank can take up to 40 minutes if supported only by laboratory concentration measurements and can be an unsafe operation. The most common measuring method of acid concentration are conductivity method and boiling point method. Conductivity method is to measure the concentration of sulfuric acid solution by using the corresponding relationship between the conductivity of liquid and concentration from different temperature. Instruments based on conductivity method are more convenient and simpler to operate. It also requires low maintenance. However, this type of instrument is not accurate when measuring acid with concentration between 93%-98% at normal working temperature. Although it is a great product, we cannot gain accurate reading at the filling station by this type of instrument. Boiling point method is based on the characteristics of different concentrations of acid with different boiling points for measurement. However, it is very hard to control boiling temperature and the heating wires are easy to burn off during operation. It also requires high maintenance. So, it is very hard to promote this type of instrument in most of large manufacturers.

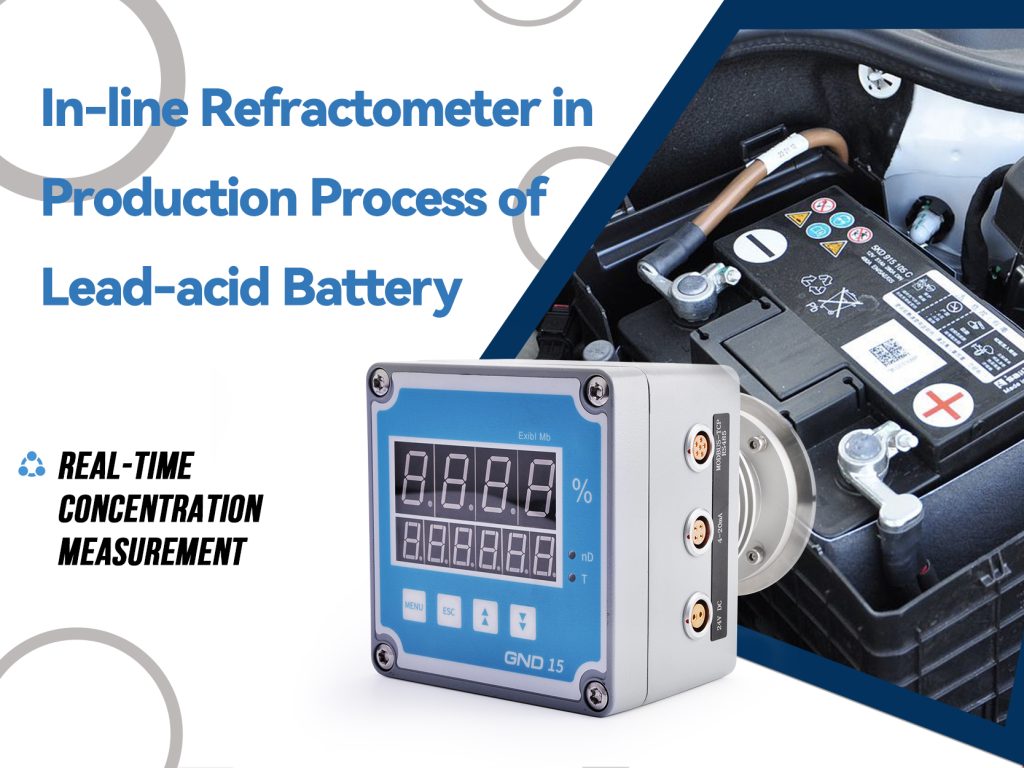

GND-15 In-line Process Refractometer Information

GND-15 In-line Process Refractometer is consisting of light source, sapphire, optical receiver and signal modulation circuit. Light source signal stability of light through the sapphire contact with measured medium, refractive index will be generated by the light source through the concentration of the measured medium. The optical receiver will calculate the refractive index of the refraction light source collected and then obtains the corresponding concentration through the data algorithm. Since the concentration will be affected by temperature, it adopts the internal temperature calibration to reduce the influence of temperature drift.

GND-15 s composed of a high-precision on-line concentration sensor, a control host integrated with a high-resolution display screen and a high-pressure automatic cleaning component. Built-in high precision (measurement accuracy up to Brix±0.1) concentration measuring element (concentration measurement square value up to Brix 0.00 to 45.00%) and temperature sensor (temperature measurement square value up to 0 to 135°C), can provide factory linear calibration and automatic temperature compensation for the measured solution value. Real time data will be both shown on the product screen and sent to control system.

Advantages for Lead-acid Battery Production

Convenient: real-time data collection without manual contact.

Stability: GND-15 adopts sapphire refraction principle with measuring accuracy up to 0.3% and large touch screen. It can display concentration %, temperature T and refractive index (nD) reading in real-time to ensure the quality of filling process.

Durability: The measuring probe is made of anticorrosion and high temperature resistant material. The outer shell is IP67 with explosion-proof level at Ex IA IIB T6 Ga. The instrument also has shock protection and high temperature resistance with process temperature up to 100 ℃.

Energy Saving: GND-15 is a convenient quantitative management and testing tool for lead-acid battery production. It provides great convenience for accurately making sulfuric acid concentration. The concentration and temperature value can be transmitted to the control system in real time, and then remotely operate the system from your control room. The integrated automatic cleaning function ensures the accuracy of concentration measurement and greatly reduces the downtime during the conversion of the canning line.

Low Maintenance: Dust and dirt can be easily wiped off by using soft cloth. The integrated automatic cleaning function makes the cleaning process simple and convenient.