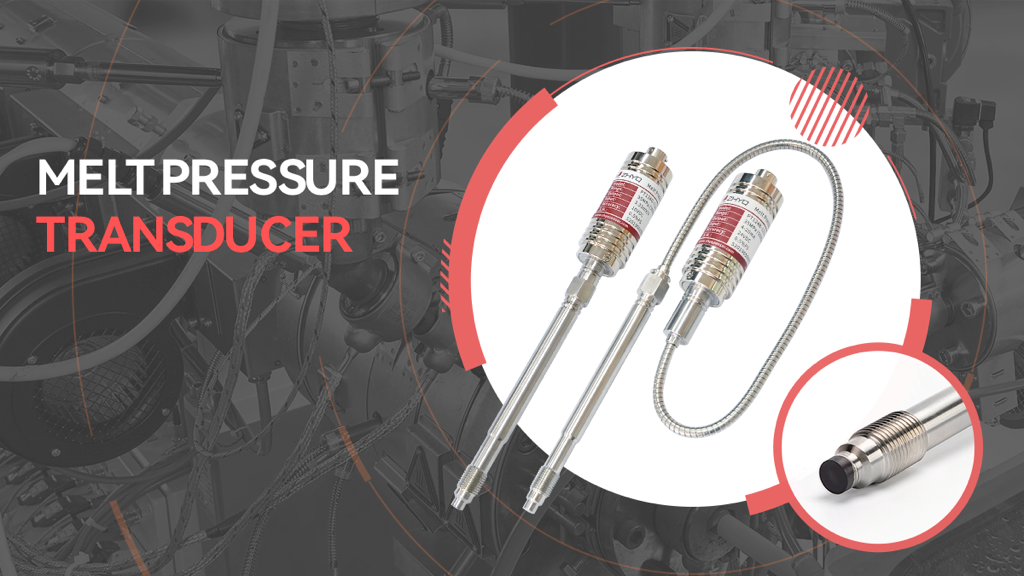

In extrusion lines, melt pressure sensors play an important role in improving melt quality, and in providing a safe environment and protecting production equipment. At the same time, melt pressure sensors are also a very sensitive component and damage easily, so proper installation and careful maintenance are important.

Melt pressure sensors in an extrusion line can be either a single sensor measuring pressure at a single point, or a series of sensors measuring the whole production line.

The following simple methods can extend the service life of pressure sensors and help users obtain accurate and reliable measurement results:

- Follow the correct installation method

Selecting proper tools to process mounting holes helps to control the size of mounting holes. In addition, proper mounting torque facilitates a good seal. However, if the mounting torque is too high, it can cause sensor slippage. Anti-slippage compound is normally used before sensor installation to avoid sensor slippage issues. - Check the size of the mounting hole

If the mounting hole is not the right size, the threaded part of the sensor can wear easily during installation. This will not only affect the sealing performance of the equipment, but also make the sensor unable to play its full role, and may even cause safety issues. Thread wear can only be prevented by proper mounting holes (thread industry standard 1/2-20 UNF 2B). Mounting holes can usually be tested with mounting hole gauges to make proper adjustments. - Keep the mounting holes clean

It is very important to keep the mounting hole clean and avoid fluid clogging to ensure the normal operation of the equipment. Before cleaning extruders, all sensors should be removed from the barrel to avoid extra damage. When the sensor is removed, it is possible for the molten material to flow into the mounting hole and harden. If this residual molten material is not removed, it may cause damage to the top of the sensor when it is reinstalled. A cleaning kit can remove these melt residues. However, repeated cleaning procedures can deepen damage to sensors caused by mounting holes. If this happens, measures should be taken to raise the sensor position in the mounting hole. - Choose the right location

When the sensor is installed too close to the upstream of the production line, the unmelted material may wear the top of the sensor; If the sensor is installed too far back, there may be a stagnant zone of molten material between the sensor and the screw stroke, where the melt may degrade and the pressure signal may be transmitted distorted; If the sensor is too deep into the barrel, the screw may touch the top of the sensor during rotation and cause damage. In general, sensors can be located on the barrel in front of the screen, in front and behind the melt pump, or in a mould. - Clean the sensor

All sensors should be removed before cleaning the extruder barrel with a wire brush or special compound. Because both cleaning methods can cause damage to the vibration film of the sensor. When the barrel is heated, the sensor should also be removed and wiped on top with a soft cloth that will not cause wear, and the holes in the sensor should also be cleaned with a clean drilling machine and guide sleeve. - Keep instrument in a dry working environment

Although the circuitry of the sensors is designed to withstand harsh extrusion conditions, most sensors are not completely waterproof and normal operation can be affected in wet conditions. Therefore, ensure that the water in the water-cooling device of the extruder barrel won’t leak, otherwise it will adversely affect the sensor. If the sensor has to be exposed to water or humidity, choose a special sensor with strong water resistance. - Avoid low temperature interference

During the extrusion process, there should be sufficient “soaking time” for the plastic raw material from solid to molten state. If the extruder has not reached the operating temperature before the start of production process, the sensor and the extruder will be damaged to a certain extent. In addition, if the sensor is removed from the cold extruder, the material may adhere to the top of the sensor and cause damage to the vibration film. Therefore, before removing the sensor, it should be confirmed that the temperature of the barrel is high enough and the material inside the barrel is in a softened state. - Avoid pressure overload

Even if the overload design of the pressure measuring range of the sensor can reach up to 50% (the ratio beyond the maximum range), the risk should be avoided as far as possible for the safety of the operation of the equipment. In general, the optimal range of the selected sensor should be twice the measured pressure, so that the sensor can be protected from damage even when the extruder is operating at extremely high pressure.