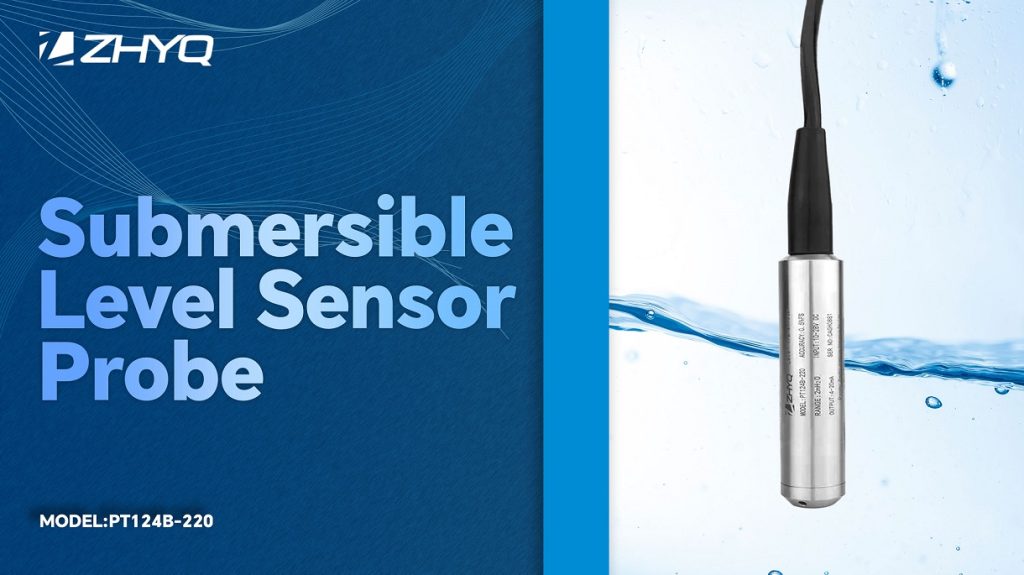

Throw-in type level transmitter, also known as hydrostatic pressure level sensor. It is an extension and development of advanced pressure transmitter technology in different applications. This type of transmitter is designed base on the principle of linear relationship between the measured hydrostatic pressure and the height of the liquid. It uses the piezoresistive effect of diffused silicon or ceramic sensors or capacitive pressure sensor converts static pressure into electrical signal. Through temperature compensation and linear correction, output signal will then be converted to 4-20 milliampere or 0-5 volt. In field installation, the sensor section can be directly put into the testing medium and the transmitter section of the instrument can be fixed by flange or bracket connection.

Throw-in type level transmitter can be used to measure height and pressure of water, oil and low concentrated testing medium. This transmitter features:

- High precision with great stability;

- Simple and convenient installation (can be directly put into testing medium);

- Integrated structurewith no separable parts;

- High reliability with long service life;

- Wide range of temperature compensation, testing result will not be affected by any changes from testing medium;

- Power reverse polarity protection and overload current limiting protection;

There are so many factors need to be taken into consideration when choosing the most suitable throw-in type level transmitter for specific application. The following factors need to be specially paid attention to:

- Confirm testing medium and its nature (such as corrosiveness, thickness, particle content, etc.). For example, anti-corrosion liquid level transmitter can be used in medium with high corrosiveness and capacitanceliquid level transmitter can be used to test medium with high solid particle contents;

- Understand signal output requirement for the application. The output signal needs to match input signal of PLC, DCS or instrument devices from the whole system. Common output signals are 4-20mA, 0-20mA, 1-5V, 0-10V and other digital signals;

- Find out available power supply – i.e., power input for level transmitter. 24Vdc and 220Vac are the most common power supplies. Special voltage according to different geographical locations are 12Vdc, 15Vdc, 48Vdc and 110Vac;

- Need to know the process connection type and size. Liquid level transmitter is generally installed by screw or flange installation;

- Also need to know the accuracy requirements for the application. Standard accuracy can be used in applications with no special requirement;

- Working environment is also an important effect. Anti-explosion level transmitters are required to use in power plants and chemical plants. In chemical plants, anti-corrosion is also a required feature for instruments;

In addition, there is a very special situation where measurement requires use of differential pressure level transmitter. Differential pressure level transmitter is often installed at the bottom of the liquid tank. Using gauge pressure signal reflects liquid level. This situation is often seen in process of pharmaceutical, food & beverage and chemical industries. In these processes, tanks are often under pressure where throw-in type level transmitters are not able to work.

In conclusion, throw-in type level transmitter as a common type of liquid level transmitter is widely used across varies industries. To know how to choose the most suitable instruments with best performance is essential for operators.